Full range of sustainable and repeatable site-specific qualification programs that assure your employees have the knowledge and skills to deliver reliable, consistent, and safe plant operations while decreasing operating and maintenance costs. This proven approach to qualification leads to:

- Maximized efficiency and availability of specific OEM equipment and increase reliability, production, and out-put on a facility-wide basis.

- Assurance of regulatory compliance, fulfillment of certification requirements and the proper knowledge base and skillset for each position from shift to shift.

PIC Group’s comprehensive qualification program is built upon a combination of written documentation design, that promotes optimal knowledge transfer, and proven training methodology that enables customers to take control of facility performance. A qualification program that includes Instructor Led Training (ILT) to Web based reinforcement and with the ESP3 Learning Management System (LMS) documents proficiency and establishes clear opportunities for improvement.

TRAINING SOLUTIONS

Site-specific qualification programs that assure reliable, consistent, safe plant or facility operation and maintenance.

The consistent operation and optimal performance of a power plant or manufacturing facility is essential to meeting the goals and objectives of that facility. PIC Group’s site-specific qualification programs assure reliable, consistent, safe plant operations as well as decreased costs through the reduction or elimination of operator errors, equipment failures, and inefficiencies caused by inadequately trained employees.

A four-step training process that assures a consistent knowledge base and repeatable job skills from operator to operator, shift to shift and generation to generation on a facility-wide basis.

PIC Group’s organizational training solutions and learning strategies, tailored through a four-step, needs based training model to the unique needs of your business, ensure optimal transfer of knowledge and increased skill levels on either a one-off or continuous basis. Customizable training programs are presented through classroom instruction, on-the-job training and through PIC Group’s e-Learning platform and Learning Management System (ESP3).

- Training Needs Assessment

- Training and Qualification Programs

- Online Training Portal (ESP3)

- Learning Management System (LMS)

- Site specific training material

- Animated training material

- Train the Trainer: Lesson Plans, Exams, and Proficiency

NCCER Certified: CORE, Safety Performance & Skill Assessment

DOCUMENTATION SOLUTIONS

Well written procedures ensure consistency in operation, a consistent base of knowledge, a foundation for training and a platform for continuous improvement.

PIC Group’s quality and depth of content combined with methodology of composition produce technically accurate, easy-to-use procedures that improve safety, reduce risk, ensure efficient predictable operation and compliance with regulatory requirements.

- Integrated operating manuals with customized processes, procedures, and diagrams that combines and integrates the plant’s systems to guide the consistent operation of a plant and reduce the risk of costly mistakes.

- Precise procedural documentation that begins with the understanding of a plant’s operating systems and provides detailed procedural instructions, creating a consistent base of knowledge with which to improve efficiency, and overall quality.

- As built documentation that ensures an accurate layout and distribution of a plant, improves accuracy and efficiency through error reduction, increases productivity by saving planning time and labor hours, and establishes a foundation for future upgrades or renovations.

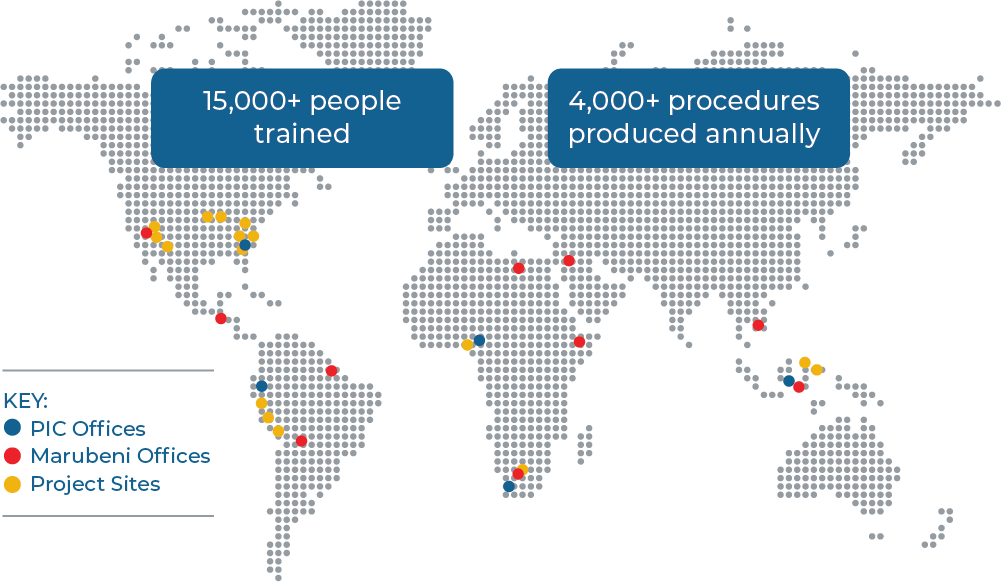

For more than 20 years, PIC Group has published over 4,000 process and procedure documents annually for use in the electronic programs and platforms that enable the quick, efficient, and smooth commissioning and startup of new plants, as well as the operation and maintenance teams for existing plants to consistently execute to plant compliance, performance and commercial management requirements.

Documentation includes:

- System Descriptions, Startup and Shutdown Procedures

- Integrated Startup / Shutdown Procedures

- Standard Operating Procedures and Plant Operating Manuals

- Abnormal, Emergency or Alarm Response Procedures

- Infrequent Operating Procedures

- Equipment Maintenance Procedures & Work Packages

- Flushing and Purge Procedures

- Qualification Cards

- Commissioning Procedures

- Turnover Packages

- System and Equipment Isolation Procedures

- Occupational Health & Safety Procedures

- Regulatory and Compliance Procedures

- Administrative Manuals and Procedures

Related Projects

Southern Companies: USA

Southern Companies: USA

O&M Procedures and Training for Coal and Natural Gas Facilities

Engie (GDF Suez): Thailand

Engie (GDF Suez): Thailand

O&M Manual; 2x LM6000 Gas Turbine; 1x Mitsubishi Steam Turbine; Cogeneration Facility

Project Locations